In today's fast-paced world, where sustainability and energy efficiency are paramount concerns, the integration of energy-efficient electronic components in commercial appliances is not just a trend but a necessity. These components not only reduce energy consumption but also contribute to cost savings and environmental conservation. In this comprehensive guide, we delve into the significance of energy-efficient electronic components in commercial appliances, explore examples of such components, and examine their diverse applications across various sectors.

Introduction

Commercial appliances play a pivotal role in numerous industries, including hospitality, healthcare, food service, and retail. From refrigeration units to HVAC systems, these appliances are essential for smooth operations. However, traditional appliances often consume substantial amounts of energy, contributing to high utility bills and environmental degradation. This is where energy-efficient electronic components come into play, offering innovative solutions to mitigate energy consumption and enhance sustainability.

The Significance of Energy-Efficient Electronic Components

Energy-efficient electronic components encompass a wide range of technologies designed to optimize energy usage while maintaining or improving performance. These components are engineered to minimize power losses, increase operational efficiency, and reduce heat generation, thereby extending the lifespan of appliances and lowering overall operating costs. By integrating energy-efficient components, manufacturers can meet regulatory standards, satisfy consumer demands for eco-friendly products, and gain a competitive edge in the market.Examples of Energy-Efficient Electronic Components

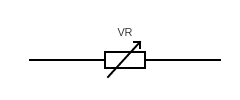

1. Variable Frequency Drives (VFDs) :

VFDs are electronic devices used to control the speed and torque of electric motors in appliances such as ventilation fans, pumps, and compressors. By adjusting the motor's frequency and voltage according to the load requirements, VFDs optimize energy usage and prevent unnecessary power consumption during low-demand periods. This results in significant energy savings and improved motor efficiency.

2. LED Lighting Systems:

LED (Light Emitting Diode) lighting has revolutionized the energy efficiency of commercial appliances, particularly in the realm of refrigeration and display units. Compared to traditional incandescent or fluorescent lighting, LEDs consume significantly less energy while providing superior illumination. Moreover, LED lights have a longer lifespan and produce less heat, reducing the strain on cooling systems and further enhancing energy efficiency.

3. Power Factor Correction (PFC) Modules:

PFC modules are electronic circuits utilized to improve the power factor of electrical systems by reducing reactive power losses. In commercial appliances with inductive loads, such as refrigeration compressors and HVAC equipment, PFC modules ensure that the power drawn from the grid is utilized more effectively, minimizing energy wastage and optimizing overall system efficiency.

4. Smart Sensors and Controls:

Smart sensors and control systems play a crucial role in optimizing energy usage and enhancing operational efficiency in commercial appliances. These components utilize advanced algorithms and data analytics to monitor environmental conditions, occupancy levels, and usage patterns, allowing appliances to adjust their operation dynamically. For instance, smart thermostats in HVAC systems can adapt cooling or heating output based on occupancy and ambient temperature, resulting in significant energy savings without compromising comfort.

5. Energy-Efficient Motors:

Motors are ubiquitous in commercial appliances, powering everything from pumps and fans to conveyors and compressors. Energy-efficient motors, equipped with advanced designs and materials, minimize electrical losses and mechanical friction, thereby reducing energy consumption and heat generation. Variable-speed motors, in particular, allow appliances to operate at optimal speeds based on demand, further enhancing energy efficiency.

Applications of Energy-Efficient Components in Commercial Appliances

1. Refrigeration Units:

Energy-efficient electronic components play a critical role in refrigeration systems used in supermarkets, restaurants, and food processing facilities. By incorporating technologies such as variable-speed compressors, LED lighting, and smart controls, manufacturers can create refrigeration units that maintain precise temperature levels while minimizing energy consumption and environmental impact.

2. HVAC Systems:

Heating, ventilation, and air conditioning (HVAC) systems account for a significant portion of energy usage in commercial buildings. Energy-efficient components such as VFDs, PFC modules, and smart thermostats enable HVAC systems to operate more intelligently, adjusting airflow and temperature settings based on occupancy, weather conditions, and time of day. This results in substantial energy savings and improved indoor comfort.

3. Commercial Lighting Fixtures:

LED lighting fixtures equipped with energy-efficient drivers and controls are widely used in commercial spaces such as offices, retail stores, and warehouses. These fixtures offer superior energy efficiency, longevity, and flexibility compared to traditional lighting technologies, allowing businesses to reduce lighting-related energy expenses and maintenance costs.

4. Food Service Equipment :

Energy-efficient electronic components are increasingly integrated into various food service equipment, including ovens, grills, fryers, and dishwashers. By optimizing heating elements, motors, and control systems, manufacturers can develop appliances that deliver precise cooking results while conserving energy and reducing operating costs for businesses in the hospitality industry.

5. Laundry Appliances :

In commercial laundries, energy-efficient motors, variable-speed drives, and smart controls are employed in washing machines, dryers, and ironing equipment to minimize energy consumption and water usage. These components not only lower utility bills but also enhance the overall efficiency and throughput of laundry operations.

Conclusion

The adoption of energy-efficient electronic components in commercial appliances represents a significant step towards achieving sustainability and reducing the carbon footprint of businesses across various industries. By harnessing the power of innovative technologies such as VFDs, LED lighting, smart sensors, and energy-efficient motors, manufacturers can develop appliances that deliver superior performance, lower operating costs, and contribute to a greener future. As businesses continue to prioritize energy efficiency and environmental responsibility, the demand for energy-efficient electronic components in commercial appliances is poised to grow, driving further innovation and progress in the field.

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

%20and%20Earth.png)