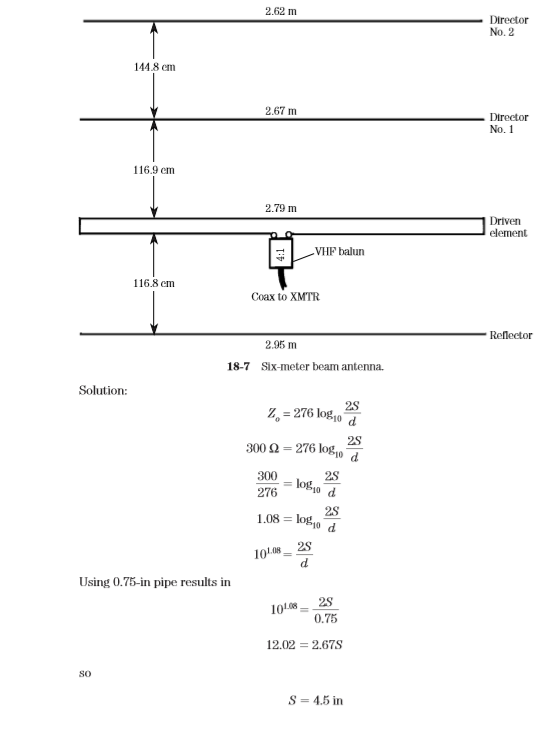

Figure 18-8 shows the construction details for a six-element 2-meter Yagi beam antenna. This antenna is built using a 2 2-in wooden boom and elements made of either brass or copper rod. Threaded brass rod is particularly useful, but not strictly necessary.

The job of securing the elements (other than the driven element) is easier when threaded rod is used, because it allows a pair of hex nuts, one on either side of the 2 2-in boom, to be used to secure the element. Nonthreaded elements can be secured with RTV sealing a press-fit. Alternatively, tie wires (see inset to Fig. 18-8) can be used to secure the rods.

A hole is drilled through the 2 2 to admit the rod or tubing. The element is secured by wrapping a tie wire around the rod on either side of the 2 2, and then soldering it in place. The tie wire is no. 14 to no. 10 solid wire.

Mounting of the antenna is accomplished by using a mast secured to the boom with an appropriate clamp. One alternative is to use an end-flange clamp, such as is sometimes used to support pole lamps, etc.

The mast should be attached to the boom at the center of gravity, which is also known as the balance point. If you try to balance the antenna in one hand unsupported, there is one (and only one) point at which it is balanced (and won’t fall). Attach the mast hardware at, or near, this point in order to prevent normal gravitational torques from tearing the mounting apart.

The antenna is fed with coaxial cable at the center of the driven element. Ordinarily, either a matching section of coax, or a gamma match, will be needed because the effect of parasitic elements on the driven element feedpoint impedance is to reduce it.