A longwave (LW) antenna is an antenna that is designed to transmit or receive radio waves in the longwave band, which ranges from 150 to 525 kilohertz (kHz). LW antennas are typically large and cumbersome, as the wavelength of longwave radio waves is very long.

Here are some of the most common types of LW antennas:

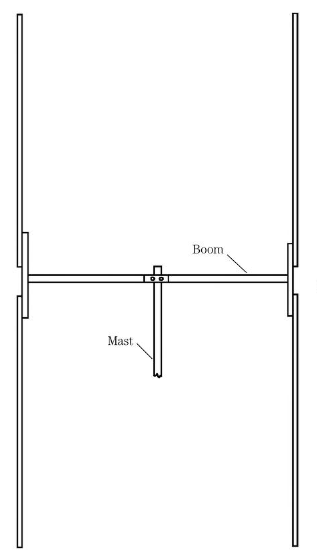

- Vertical antenna: A vertical antenna is the simplest type of LW antenna. It consists of a single vertical conductor, such as a metal rod or pipe. The length of the antenna should be one-quarter of the wavelength of the radio waves it is designed to transmit or receive.

- Loop antenna: A loop antenna is a circular or elliptical antenna. It is made up of a single conductor that is bent into a circle or ellipse. The diameter of the loop should be one-half of the wavelength of the radio waves it is designed to transmit or receive.

- Ground-plane antenna: A ground-plane antenna is a vertical antenna that is surrounded by a ground plane. The ground plane is a conducting surface, such as a metal sheet or a network of wires, that is placed below the antenna. The ground plane helps to improve the radiation pattern of the antenna.

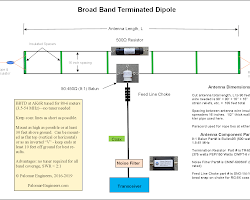

- Terminated antenna: A terminated antenna is an antenna that is terminated in a resistor. The resistor absorbs the radio waves that are not transmitted or received by the antenna. This helps to prevent the antenna from radiating harmful interference.

The design of an LW antenna depends on a number of factors, including the frequency band it is designed to operate in, the desired radiation pattern, and the amount of space available.

If you are planning to build an LW antenna, it is important to consult with a qualified antenna engineer to ensure that the antenna is designed correctly.

Here are some of the things to consider when designing an LW antenna:

- Frequency band: The frequency band that the antenna is designed to operate in will determine the length of the antenna.

- Radiation pattern: The radiation pattern of an antenna describes how the radio waves are emitted from the antenna. There are many different radiation patterns that can be used for LW antennas.

- Space available: The amount of space available will determine the size and shape of the antenna.

- Cost: The cost of the antenna will depend on the materials used and the complexity of the design.

Once you have considered these factors, you can start designing your LW antenna. There are many resources available to help you design an antenna, such as books, websites, and software programs.

.PNG)